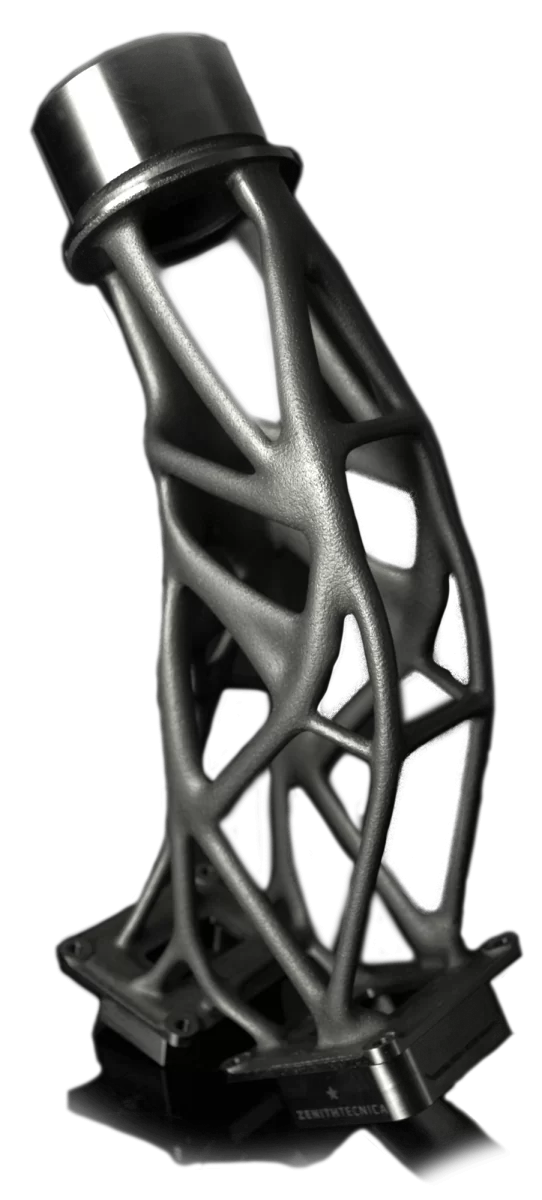

The future of manufacturing is here. Titanium Additive Manufacturing (AM) opens the door for designs that could not previously be imagined. Take advantage of the new possibilities and pathways to explore through Zenith Tecnica's collaborative contract metal manufacturing services.

We take your ideas and turn them into a reality using cutting-edge technology and world-leading expertise.

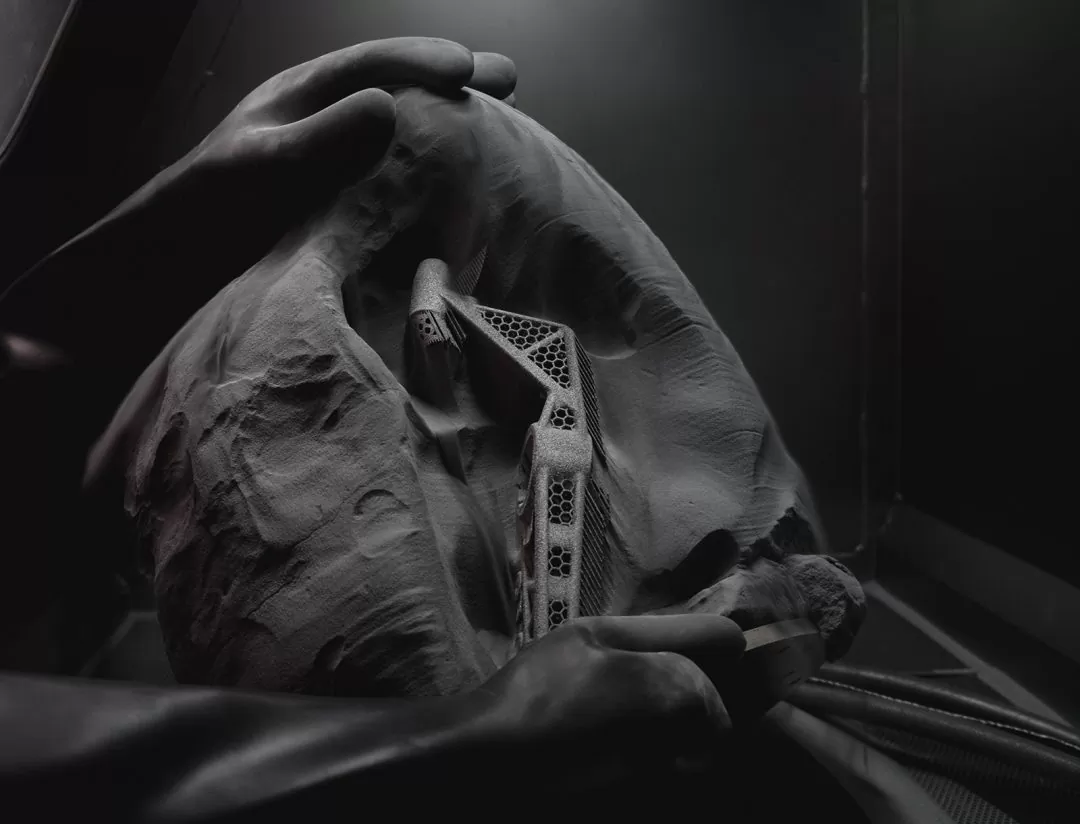

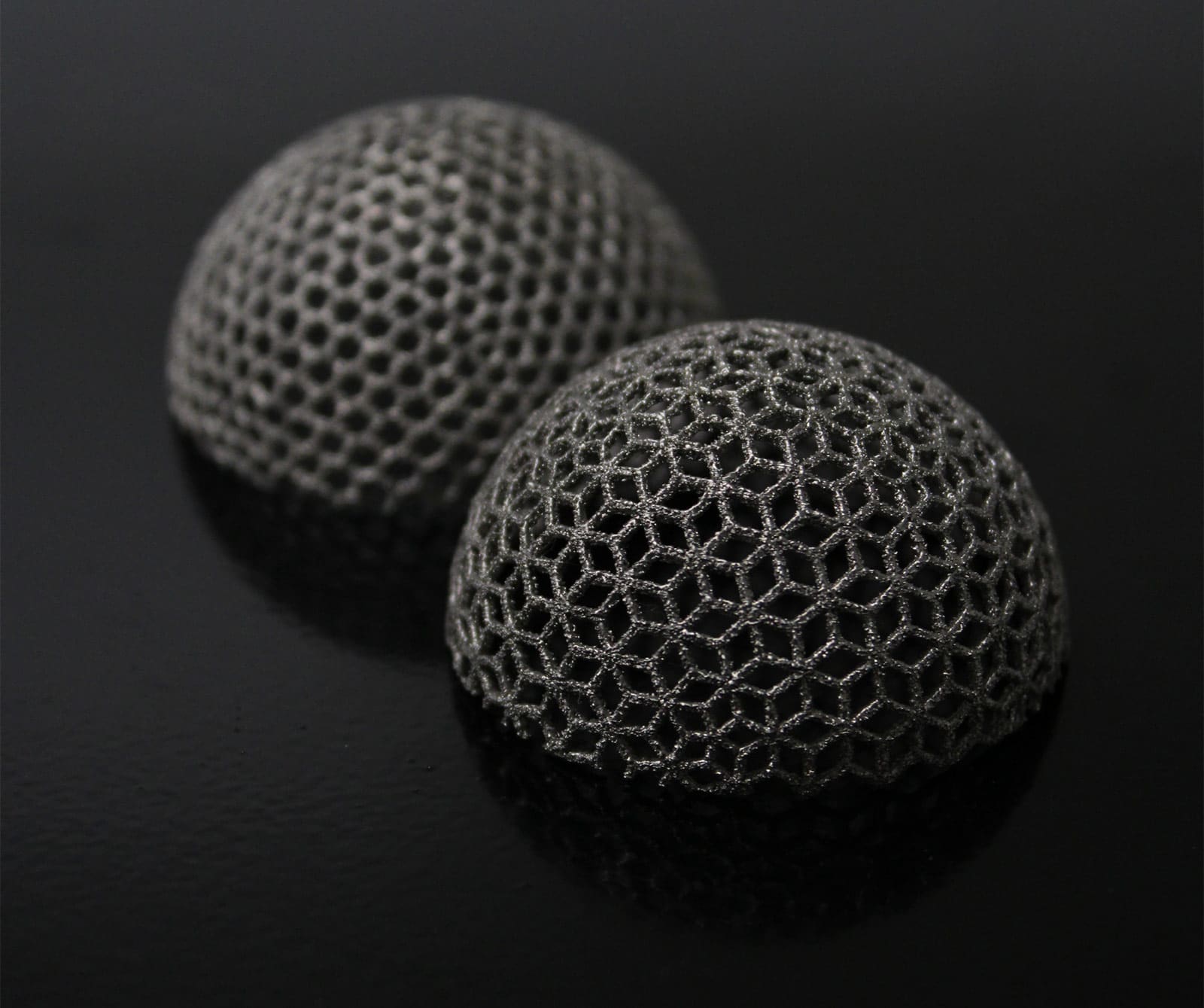

EBM (Electron Beam Melting) is a powerful and unique form of metal 3D Printing. Paired with Titanium, EBM enables incredibly productive builds of strong, light and immediately stress-relieved parts. As a powder-bed fusion process, we only use the material required. Meaning with our strong powder recovery and recycling system in place, we remain a sustainable option for manufacturing.

Suitable for a plethora of worldwide industry applications, EBM allows for tall, and thin-walled components, the use of strong and lightweight materials (Ti6Al4V) and a productive build environment through the ability to stack parts throughout the entire available volume.