SMALL TO BATCH

MANUFAFCTURING

Our team of engineers work swiftly with you to manufacture parts in a timely and economically friendly manner. Whether you require a one-off project or a series of products, we have a large capacity to service your needs on our ride-share or dedicated builds.

SCALABLE

PRODUCTION

Our team will collaborate with you to define a quality plan and validate a process to meet your monthly, quarterly, or annual requirements on time. By using Additive Manufacturing we can find the most cost-effective solution using ride-share builds or scale our capacity of dedicated builds to suit the volume of production required.

SERVICES

While at our core, we manufacture titanium components; our services go far deeper.

Titanium Additive Manufacturing using Electron Beam Melting is an incredibly powerful process that is being taken advantage of all around the globe.

We take your designs and 3D Models and make them a reality. Unlocking efficiencies that often could not be achieved using traditional manufacturing options.

STANDARD OPERATIONS INCLUDE:

OPTIONAL OPERATIONS INCLUDE:

To learn more about the technical capabilities of all of our services and specifications including wall thickness, dimensions and tolerances, please contact our team to request a copy of our EBM Design Guidelines.

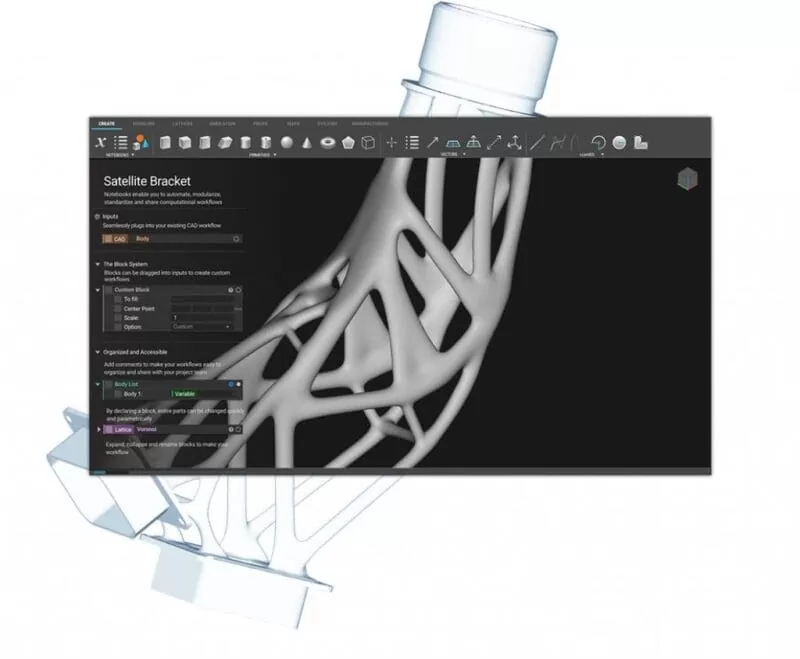

Our team will collaborate with you to enhance your design for EBM manufacture, and enable you to leverage the benefits of EBM additive manufacturing. With some of the highest running hours utilizing EBM technology in the world, as well as the highest level of OEM training our team has a deep understanding and wealth of knowledge ready for you to tap into.

CAPABILITIES:

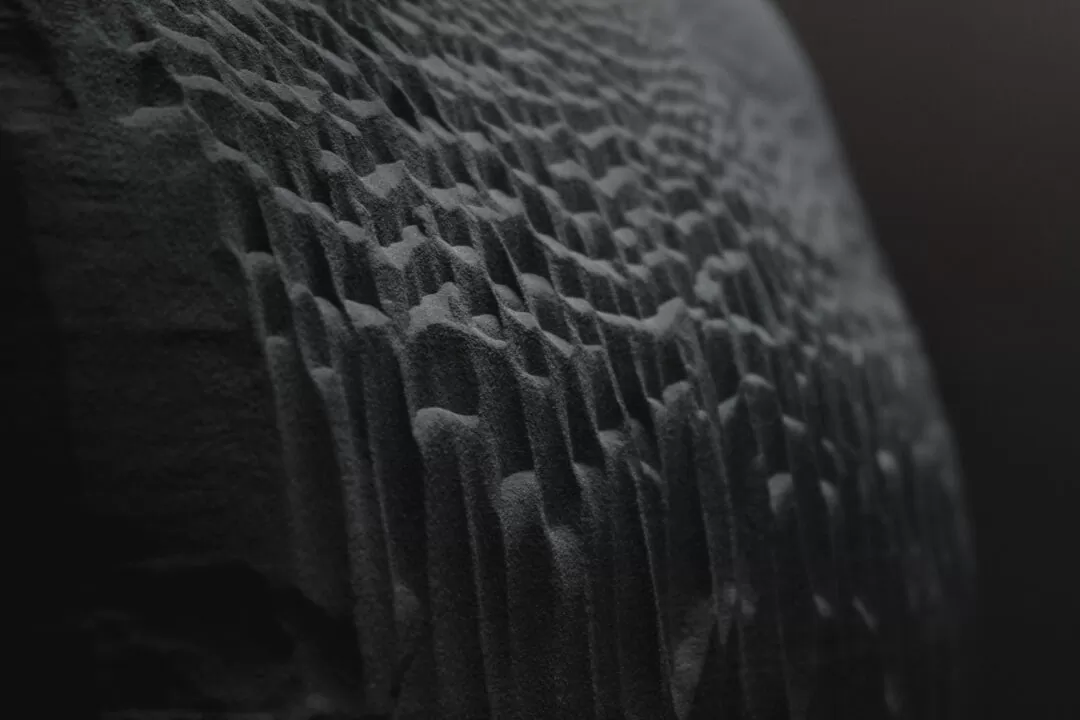

Lattice & Porous Structure Generation

Light-weighting

Mass customisation

Complex geometry

Find out what you need to provide to get a quote here

Surface finishing and post-processing treatments are crucial in an engineered environment and are often highly dependent on the end application of the design. For example, abrasive surfaces (such as the EBM ‘as-built’ surface roughness of 16um 22um Ra) can be ideal for bonding situations, smooth surfaces can promote a more consistent flow of fluid, and machined surfaces offer improved fatigue life for high-stress use. While we are able to meet a wide range of finishing options, special consideration must be applied to ensure you are taking advantage of the most appropriate finish.

CAPABILITIES:

Surface finishing and treatment outcomes are highly dependent on the geometry and method used. For example, internal cavities and small radii can be challenging to surface finish with limited tool access.

We have multiple in-house finishing capabilities, including:

On request we can also offer:

If you require specific surface roughness or aesthetics, please note that typical surface finishing will remove approximately 0.4mm of material. If surface finishing is specified on simple geometries our team can add this material allowance, however, if the surfaces are complex we will request that you allow for this material in the model you provide to us.

It is important to note, that not all surfaces can be mirror polished, such as internal cavities and tight radii. This is highly dependent on geometry and in most cases, outside volume production will be performed manually. Please contact our team to discuss what option would suit you.

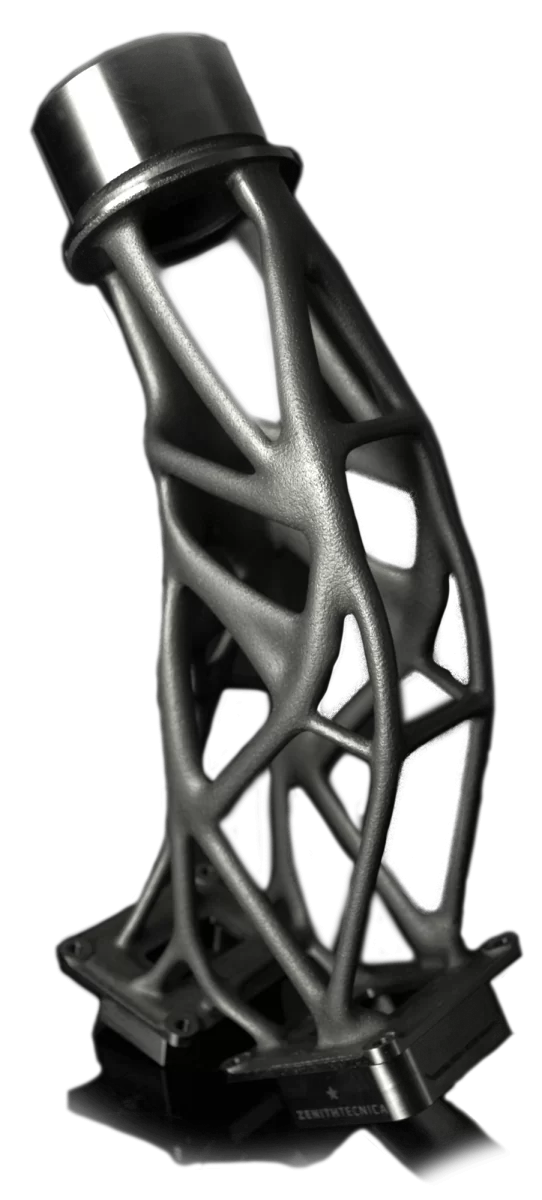

Zenith Tecnica provides the ability to mark products with branding, certifications and identification labels.

Labels allow for high levels of traceability to all materials, powder, and processes used to manufacture components. For full traceability right down to position in a build, serial numbers can be printed directly on components, or lot numbers can be laser marked during the inspection. Customers can use this capability to enable identification during assembly and traceability throughout its service life.

Zenith Tecnica Recommended Font Properties

| ||

Text Property |

Printing

| Laser Marking |

Font |

Trebuchet MS, or a simple Sans-Serif font is recommended for clarity of all characters

| |

Size (Text Height) |

4mm [11pt]

| 2.5mm [7pt] |

Depth |

Emboss or engrave by 0.4-0.6mm if you want text visible after surface finishing, engrave with min. 0.6mm

| – |

Location |

If you would like Zenith Tecnica to apply a lot number or serial number to components, please define the area to apply the label on your manufacturing drawing.

| |

HIP heat treatment is commonly used in the Aerospace and Medical industries to improve material performance. We work closely with our US-based partner to provide our customers with access to this service. The HIP process puts components under high pressure and temperature to improve the internal structure.

For highly loaded or dynamically loaded thin-walled geometries, our team advises HIP heat treatment and qualification with physical testing. For the best material performance, HIP should be used in conjunction with surface finishing to improve both the inside and outside of the material. HIP will typically require an additional 2 weeks of lead time to be processed.

CAPABILITIES:

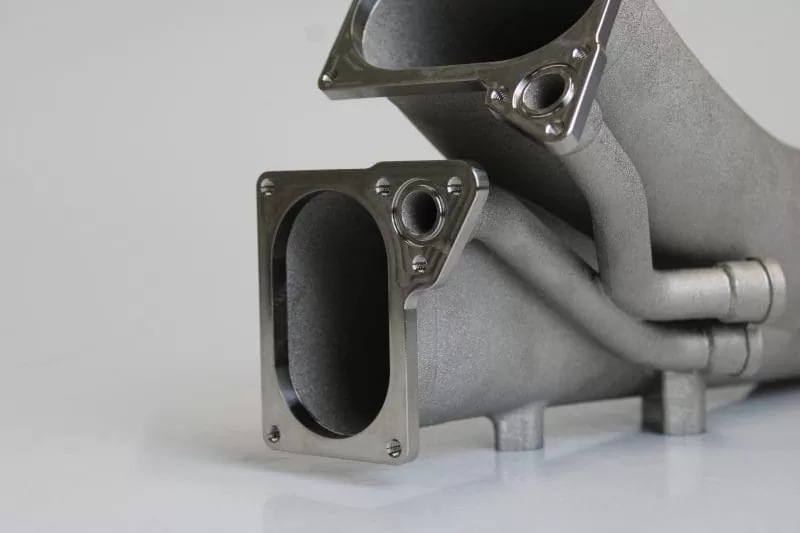

We work closely with our partners who are experts at working with AM designs and Titanium alloy. Together we provide the ability to machine near-net EBM components which offers a hybrid manufacturing approach. This enables the benefits and flexibility of Additive Manufacturing with the accuracy of Machining. Machining is often used in conjunction with EBM for components that require tight assembly tolerances.

CAPABILITIES:

Please contact our team to request your copy of our Technical FAQ to learn what Geometric Dimensions and Tolerances (GD&T) are achievable.

Our metrology capabilities enable us to validate that components meet our customer’s specifications. Additive Manufacturing produces complex geometries which are traditionally challenging to measure and conform. This is why we have 3D scanners and a vision system to perform measurement and analysis of 3D surface profiles.

CAPABILITIES:

Zenith Tecnica offers material and product testing through 3rd party accredited labs. We recognise the importance of providing an independent evaluation of our process to ensure confidence in the components we manufacture.

Every build that we run on our EBM machines includes test specimens for continuous material validation and traceability to demonstrate conformance to ASTM F2924.

CAPABILITIES:

You can order the following test certificates for any build:

We can also include specimens at your request for many other tests, including but not limited to:

Contact us today to discuss your individual requirements.

Zenith Tecnica has qualified our EBM machines to produce a wide range of spacecraft components and medical devices. We continually monitor and control our processes so to ensure they are operating within set limits to provide our customers with confidence in the components they receive.

We have a standard quality plan, sometimes known as a standard operating procedure, that dictates the requirements for every part produced at Zenith Tecnica. Some customers may have additional requirements and our team captures these in a tailored quality plan that outlines any parts of the process that are different to standard.

We can supply a certificate of conformance with your orders to provide traceability to all standards and specifications used during manufacturing.

CAPABILITIES:

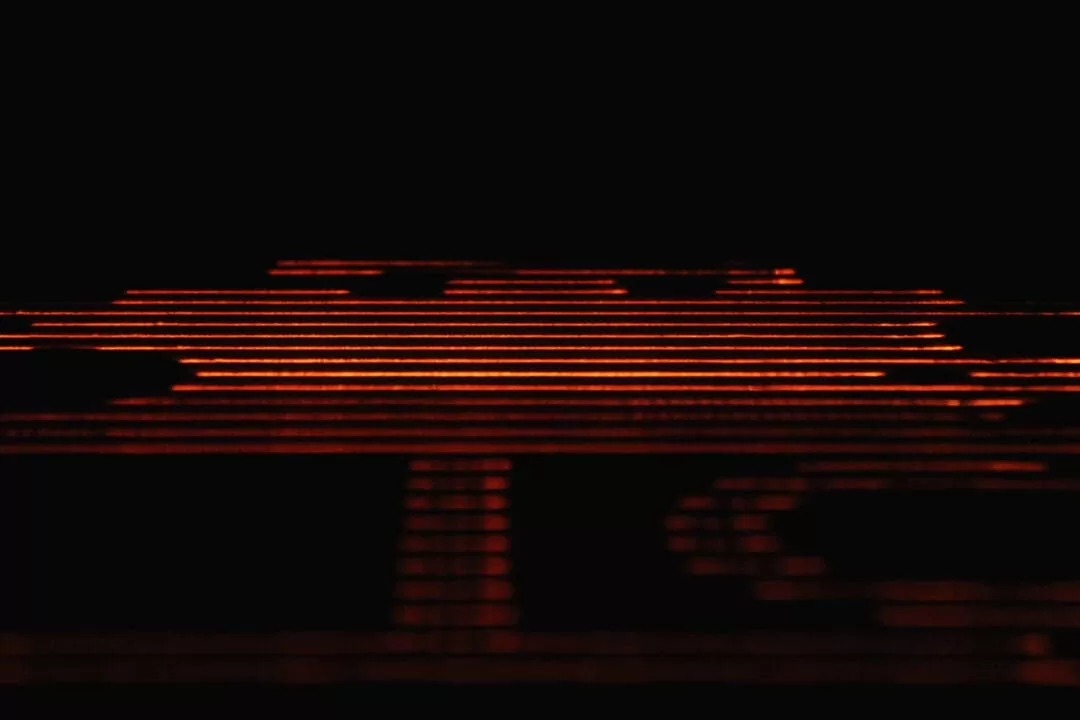

Electron Beam Melting (EBM) is a Powder Bed Fusion Additive Manufacturing (AM) process. Utilising an incredibly powerful beam of electrons, this form of AM heats and selectively fuses metal powder together.

The process begins with an extremely thin layer of metal powder spread across a build plate and pre-heated. Once the desired heat is achieved, the beam accurately melts areas of powder at speeds of up to 8000m/s, which is approximately 28,800 kilometres per hour.

Once the layer has finished being melted, the plate descends a distance less than the average width of a human hair. From here a new spread of metal powder is applied and the next layer begins. The design of the finished part is achieved through the creation of a 3D CAD Model that is digitally sliced into thousands of individual layers, acting as a blueprint for the beam to follow.

Titanium is an incredibly versatile material. Yet, it has remained remarkably underutilized as it was previously difficult to take advantage of. With the progression in technology and growth of powder bed fusion 3D Printing, anyone can now unlock the potential of titanium.

With such a capable material at our fingertips, we have been able to concentrate our efforts towards becoming world leaders in the art of titanium alloy manufacturing. Through our commitment to titanium, coupled with our humidity and temperature-controlled machine environment, reduces any risk of cross-contamination and material impurities.

SERVICES

Find out why industries around the world are choosing EBM built titanium parts for their projects.

SERVICES

Find out why industries around the world are choosing EBM built titanium parts for their projects.

Production of unique and complex geometries can be achieved with Additive Manufacturing (AM). EBM enables high productivity manufacturing of tall and thin-walled components, parts with large cross-sectional changes and the ability to consolidate assemblies.

Additive Manufacturing can exploit the high strength-to-weight ratio of titanium better than other traditional manufacturing methods by making it possible to produce thin and complex geometry components.

Components can be designed using the latest optimisation techniques to reduce mass. Our customers have optimised these assemblies to reduce mass for thermal loading in space and mechanical loading in many high-performance applications.

Titanium is naturally corrosion-resistant, assisting its performance in harsh environments such as saltwater. In particular, titanium pairs well with carbon fibre composites due to their position on the galvanic series. This pairing leads to longer service life through reduced festering.

Titanium is widely used in orthopedic implants due to its bio-compatible nature, corrosion resistance, and specific strength. Using AM, surgeons and implant manufacturers can create patient-specific devices on tight deadlines. This opens the possibility to incorporate metal porous structures for osseointegration to improve patient outcomes.

Zenith Tecnica chose GE Additive Arcam EBM machines as they typically fit more parts per build than alternatives. This enables filling an entire 3D build volume of parts. Combined with the speed of EBM, this results in faster lead times through the efficient build processes.

The sintered powder bed surrounding melted components in the EBM process supports thin-wall components laterally. Allowing for more design freedom with large lightweight structures.

The EBM process takes place in a vacuum chamber and maintains a high-temperature powder bed throughout the build process. The results in components being stress relieved and machineable straight after unloading without further heat treatment.

The EBM process has enough speed and power to melt large volumes and thick walls without distortion when compared with similar powder bed fusion technologies. This is useful for part consolidation and structural components which require extra material for high strength and stiffness.

Production of unique and complex geometries can be achieved with Additive Manufacturing (AM). EBM enables high productivity manufacturing of tall and thin-walled components, parts with large cross-sectional changes and the ability to consolidate assemblies.

Additive Manufacturing can exploit the high strength-to-weight ratio of titanium better than more traditional manufacturing methods by making it possible to produce thin and complex geometry components.

Components can be designed using the latest optimisation techniques to reduce mass. Our customers have optimised these assemblies to reduce mass for thermal loading in space and mechanical loading in many high-performance applications.

Titanium is naturally corrosion-resistant, assisting its performance in harsh environments such as saltwater. In particular, titanium pairs well with carbon fibre composites due to their position on the galvanic series. This pairing leads to longer service life through reduced festering.

Titanium is widely used in orthopedic implants due to its bio-compatible nature, corrosion resistance, and specific strength. Using AM, surgeons and implant manufacturers can create patient-specific devices on tight deadlines. This opens the possibility to incorporate metal porous structures for osseointegration to improve patient outcomes.

Zenith Tecnica chose GE Additive Arcam EBM machines as they typically fit more parts per build than alternatives. This enables filling an entire 3D build volume of parts. Combined with the speed of EBM, this results in faster lead times through the efficient build processes.

The sintered powder bed surrounding melted components in the EBM process supports thin-wall components laterally. Allowing for more design freedom with large lightweight structures.

The EBM process takes place in a vacuum chamber and maintains a high-temperature powder bed throughout the build process. The results in components being stress relieved and machineable straight after unloading without further heat treatment.

The EBM process has enough speed and power to melt large volumes and thick walls without distortion when compared with similar powder bed fusion technologies. This is useful for part consolidation and structural components which require extra material for high strength and stiffness.

SERVICES

Diving into the world of Titanium 3D Printing doesn’t have to be a daunting task.

01

QUOTING

& REVIEWING

Send our team of AM experts your 3D CAD model, quantities of components, and any post-processing and/or quality requirements and we will get right on providing you accurate cost breaks and lead-time schedule.

02

NESTING

& BUILDING

Based on your order quantities, we then find the most cost-effective solution for building. Whether on our regularly launched “Ride-Share” build where space is shared between customers to reduce cost, or launching one or multiple “Dedicated” builds for lower unit cost and/or larger quantities.

03

POST PROCESSING

& DELIVERY

Once the components are built, we remove any support structures, clean and inspect the part(s) and then accomplish all post-processing requirements with our in-house capability and network of trusted partners. From here, we securely package and deliver the parts right to your door.

We have structured our builds to accommodate different order quantities and requirements, while still remaining efficient.

Ride-Share Builds allow our customers who have smaller orders to still build efficiently.

Instead of launching one build per order, we can combine multiple orders into one, and tightly nest the parts together.

Dedicated Builds are the best option for scaling up production, or for orders that can utilize the entire build volume (Giving the lowest unit price).

These are launched when required, and are suitable for meeting critical deadlines.

SERVICES

01

QUOTING

& REVIEWING

Send our team of AM experts your 3D CAD model, quantities of components, and any post-processing and/or quality requirements and we will get right on providing you accurate costing breaks and lead-time schedule.

02

NESTING

& BUILDING

Based on your order quantities, we then find the most cost-effective solution for building. Whether on our regularly launched “Ride-Share” build where space is shared between customers to reduce cost, or launching one or multiple “Dedicated” builds for lower unit cost and/or larger quantities.

03

POST PROCESSING

& DELIVERY

Once the components are built, we remove any support structures, clean and inspect the part and then organize all post-processing requirements with our network of trusted partners.

At a minimum, we require:

For our team to better understand your application and provide tailored feedback, it is also best if you can provide the following:

Thank you!

We look forward to hearing from you.