Zenith Tecnica, a New Zealand-based contract manufacturer specializing in titanium 3D printing, recently marked its 5th year of partnering with leading satellite manufacturer Maxar Technologies to supply structural spacecraft flight hardware.

Since 2016, Maxar has built and launched five spacecraft with 260 titanium components produced by Zenith Tecnica using additive manufacturing (AM) processes. More than 270 additional parts are currently in production and assembly on eight other satellites.

“Maxar is committed to additive manufacturing and is a fantastic customer,” says Peter Sefont, Technical Director, Zenith Tecnica. “Its team is pragmatic and collaborates with suppliers to successfully leverage all the benefits that additive manufacturing has to offer. We are incredibly proud to be playing a part in the manufacturing of their spacecraft.”

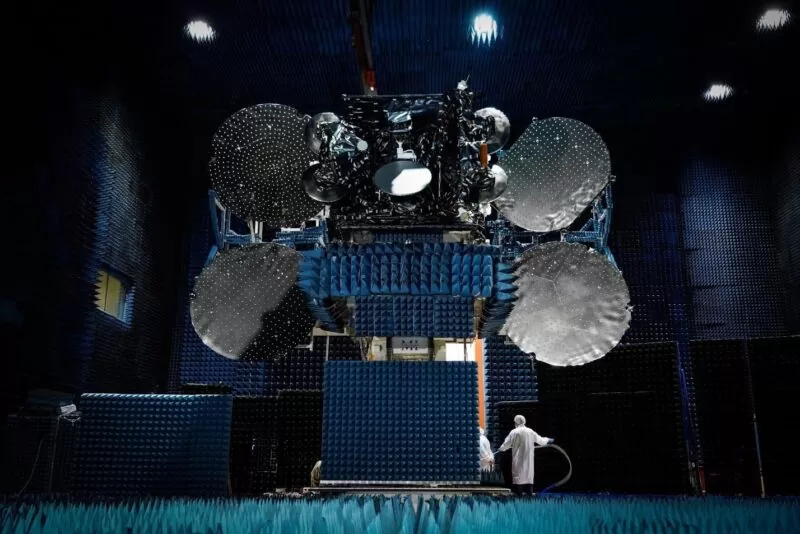

Photo – EUTELSAT 7C satellite Launched in 2019, the Maxar-built, all-electric EUTELSAT 7C satellite uses nearly 1000 additively manufactured components.

Zenith Tecnica manufactures titanium hardware for spacecraft structures. By taking advantage of AM’s mass customisation and geometrical freedoms, Zenith Tecnica’s customers can optimise hardware geometry and thermal characteristics for specific satellite features and payloads. Zenith Tecnica’s method of AM enables designs that were previously unobtainable by traditional manufacturing methods. The result of this optimisation is reduced mass, fewer pieces of hardware and improved life on-orbit.

Since the introduction of AM into the production of spacecraft components, Maxar has achieved many benefits, including improved schedule agility, reduced manufacturing costs, and increased performance of satellites.

“The team at Zenith Tecnica operates as an extension of Maxar’s team, and they always go the extra mile to ensure parts are delivered to a high standard of quality,” says Gina Ghiglieri, Additive Manufacturing Technology Manager, Maxar. “Zenith Tecnica has been with us since the first metal additive manufacturing programs at Maxar and has performed a critical role in helping define and qualify these production processes.”

Maxar was an early adopter of additive manufacturing technologies, establishing its Additive Center of Excellence in 2012. As a result, electron beam melting (EBM) titanium was qualified for flight, and by 2016, the first EBM titanium components were on-orbit.

Zenith Tecnica undertook a validation and qualification process to ensure full confidence in the additive manufacturing processes and material. The AM titanium parts are built using GE Additive Arcam EBM machines. Then the parts are heat treated, and critical assembly features are machined. Zenith Tecnica performs 3D scanning inspections to ensure all parts conform to specifications. Zenith Tecnica is one of the highest capacity EBM service bureaus in the world and can scale to meet demand.

In addition, Zenith Tecnica has a rigorous training system for all team members. The company’s senior engineers and technicians have some of the highest levels of OEM training in EBM provided by GE Additive. They are also required to have first-hand experience with every process in their facility to provide well-rounded expertise to customers. Guided by an AS9100 quality management system, Zenith Tecnica enables agile manufacturing with accuracy and reliability.